InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the “Global Selective Laser Melting In Mining Market Size, Share & Trends Analysis Report By Component (Equipment, Services, Materials, and Others),-Market Outlook And Industry Analysis 2034″

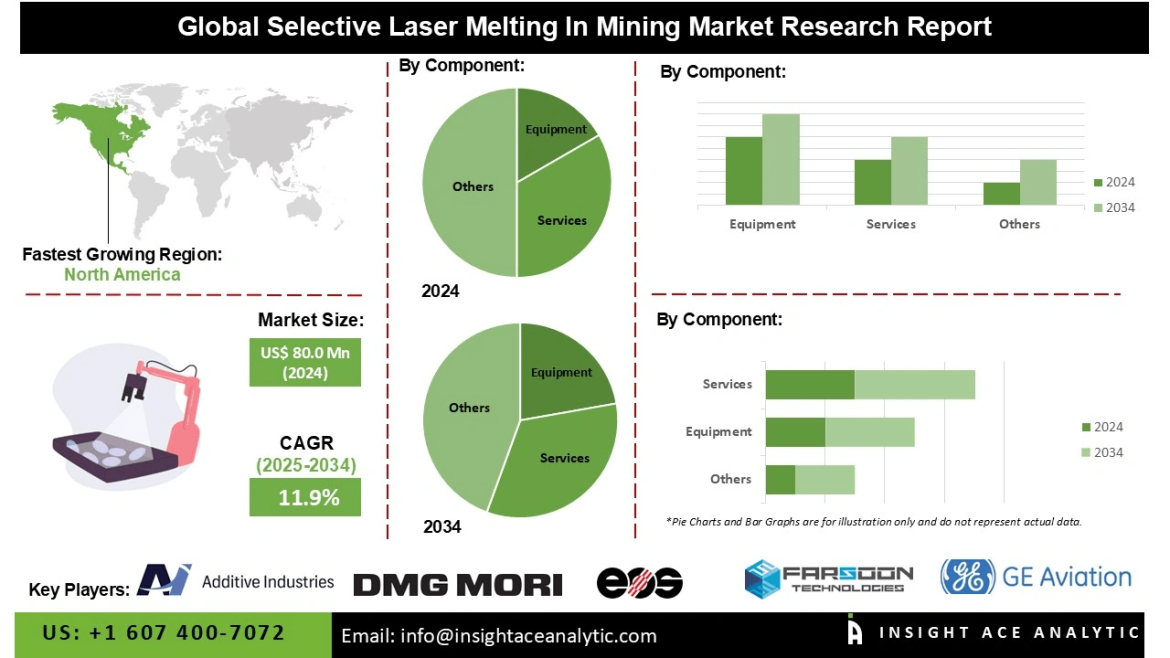

Selective Laser Melting In Mining Market Size is valued at US$ 80.0 Mn in 2024 and is predicted to reach US$ 245.1 Mn by the year 2034 at an 11.9% CAGR during the forecast period for 2025-2034.

Get Free Access to Demo Report, Excel Pivot and ToC: https://www.insightaceanalytic.com/request-sample/3290

Selective Laser Melting (SLM) is a precision-driven metal additive manufacturing technology increasingly utilized in the mining sector to produce complex, robust, and customized components for machinery and operational equipment. The process involves using a high-powered laser to selectively fuse layers of metal powders, including steel, titanium, and nickel alloys, enabling the fabrication of geometrically intricate parts that are challenging or cost-prohibitive to manufacture through conventional machining or casting methods.

Market growth is being propelled by the rising demand for on-site production of critical metal components, which enhances operational efficiency and reduces lead times. Additionally, the broader adoption of additive manufacturing technologies and continuous technological advancements in SLM systems are key factors driving the expansion of the selective laser melting market within the mining industry.

List of Prominent Players in the Selective Laser Melting In Mining Market:

- Trumpf GmbH + Co. KG

- 3T Additive Manufacturing

- Nikon SLM Solutions AG

- Renishaw plc

- Additive Industries

- Farsoon Technologies

- GE Additive

- DMG Mori AG

- EOS GmbH

- Wipro 3D

Read Overview Report– https://www.insightaceanalytic.com/report/selective-laser-melting-in-mining-market/3290

Market Dynamics:

Drivers:

The selective laser melting (SLM) market in mining is primarily driven by the increasing need for operators to minimize equipment downtime and reduce lead times for critical metal components through on-demand, near-site manufacturing. This approach mitigates reliance on extended supply chains and decreases inventory costs. Technological advancements in powder metallurgy, laser systems, and process controls—such as higher-quality metal powders, enhanced laser power, and optimized scanning strategies—have expanded the range of processable alloys while improving part performance and consistency. Additionally, the growing availability of industrial SLM machines and service bureaus, coupled with digital supply chain initiatives aligned with Industry 4.0, supports distributed manufacturing and lowers adoption barriers. Favorable economic conditions further incentivize mining companies to pilot and scale SLM for essential components, collectively contributing to market expansion.

Challenges:

The growth of the SLM market in mining is constrained by high capital and operational expenditures, including the costs of equipment acquisition, metal powder feedstock, and energy consumption, which may limit adoption among companies accustomed to conventional fabrication methods. Material limitations, such as restricted alloy options optimized for SLM, stringent powder quality and handling requirements, and concerns over powder recyclability, add complexity to production and supply chains. Moreover, the manufacture of large or heavy mining components is often constrained by SLM build-size and throughput limitations, as well as the need for extensive post-processing and heat treatment, which can increase overall production costs.

Regional Trends:

In 2024, North America led the global SLM market in mining, driven by investments in advanced 3D printing infrastructure and a focus on enhancing operational efficiency, equipment reliability, and production output. The technology allows rapid fabrication of high-strength metal parts directly from digital designs, thereby shortening lead times for essential components and reducing downtime. Sustainability goals, including material waste reduction and resource optimization, further support SLM adoption across the region.

The Asia-Pacific market is expected to witness the fastest growth during the forecast period, fueled by rising demand for advanced manufacturing technologies that enhance equipment performance, minimize operational interruptions, and optimize costs. Mining companies in countries such as China, India, and Australia are increasingly employing SLM to produce complex, high-strength components—including drill bits, wear parts, and specialized machinery—that are difficult or inefficient to fabricate using traditional methods. Expansion is further supported by increased mineral exploration activities and investments in digital and additive manufacturing technologies aimed at improving productivity and sustainability.

Unlock Your GTM Strategy: https://www.insightaceanalytic.com/customization/3290

Recent Developments:

- June 2024: With the introduction of its quad laser system and increased build volume of 325 x 325 x 400 mm, DMG MORI’s next-generation LASERTEC 30 SLM metal 3D printer represented a major advancement in additive manufacturing technology. The automated rePLUG powder module system, an interchangeable build container for quick material changes, and a floating process chamber to control thermal expansion are all aspects of the new machine.

Segmentation of Selective Laser Melting In Mining Market-

By Component-

- Equipment

- Services

- Materials

- Others

By Region-

North America-

Europe-

- Germany

- The UK

- France

- Italy

- Spain

- Rest of Europe

Asia-Pacific-

- China

- Japan

- India

- South Korea

- South East Asia

- Rest of Asia Pacific

Latin America-

- Brazil

- Argentina

- Mexico

- Rest of Latin America

Middle East & Africa-

- GCC Countries

- South Africa

- Rest of Middle East and Africa

About Us:

InsightAce Analytic is a market research and consulting firm that enables clients to make strategic decisions. Our qualitative and quantitative market intelligence solutions inform the need for market and competitive intelligence to expand businesses. We help clients gain competitive advantage by identifying untapped markets, exploring new and competing technologies, segmenting potential markets and repositioning products. Our expertise is in providing syndicated and custom market intelligence reports with an in-depth analysis with key market insights in a timely and cost-effective manner.

Contact us:

InsightAce Analytic Pvt. Ltd.

Visit: https://www.insightaceanalytic.com/

Tel : +1 607 400-7072

Asia: +91 79 72967118

info@insightaceanalytic.com